Easy to Install! NonBuren Insulator Type

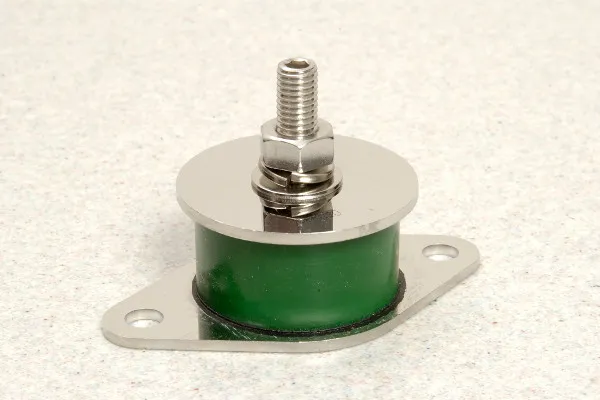

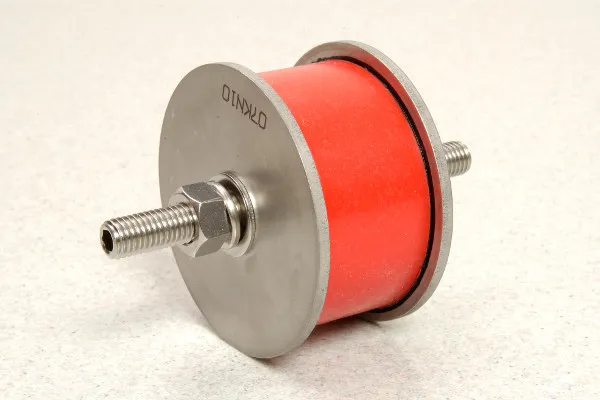

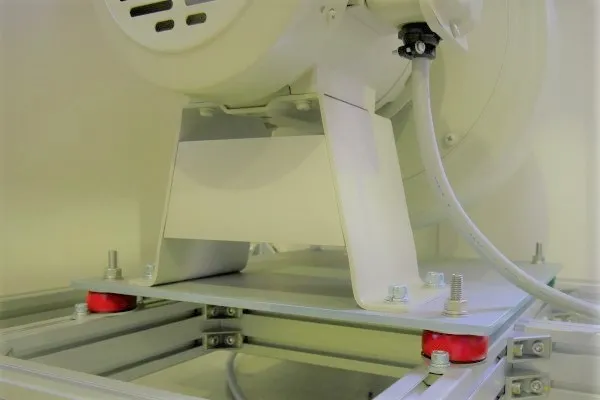

The “Round-Type NonBuren” is a circular anti-vibration insulator designed for easy installation at the four corners of heavy equipment. It’s simple to use and suitable for various environments.

Features of Round-Type NonBuren Anti-Vibration Material

Suitable for Various Weights

When used with four-point support, it can handle loads ranging from 2 kg to 1 ton.

It can also be used with a variety of equipment by adjusting the number of support points.

Soft but Durable

The strong bond with the metal fitting makes it resistant to lateral movement.It is reliable even for equipment like compressors.

Hex Wrench Insertion Hole for Easy Installation

A hex wrench slot is provided, allowing easy installation without twisting the main body.

Suitable for use in cleanrooms

The metal parts are made of SUS304 stainless steel, making it suitable for clean environments such as semiconductor manufacturing facilities.

Easy Replacement

The vibration isolating rubber has the same shape as standard round-type insulators, making it easy to install right away.

The simplest way to check the effectiveness of a vibration isolator is to look at its deflection (displacement).

If the mounted equipment is too light or too heavy, the rubber may not perform effectively. If you're not satisfied with your current anti-vibration rubber, feel free to consult us.

Available in Anti-Static Type

We also offer a conductive gel version of the round-type NonBuren for static prevention.

It’s ideal for anti-vibration carts in cleanrooms or in areas where static electricity is a concern.

Specifications – Round-Type Anti-Vibration Material NV Series

- This type is designed to be fixed with bolts on both the top and bottom, or on one side only.

- It can be used under light loads, although this is not recommended. For best performance, please use it under sufficient load.

- The single-side washer type (Type B) can be mounted directly onto flat surfaces such as floors.

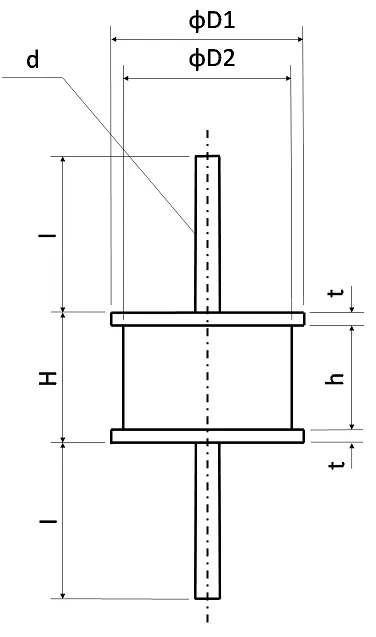

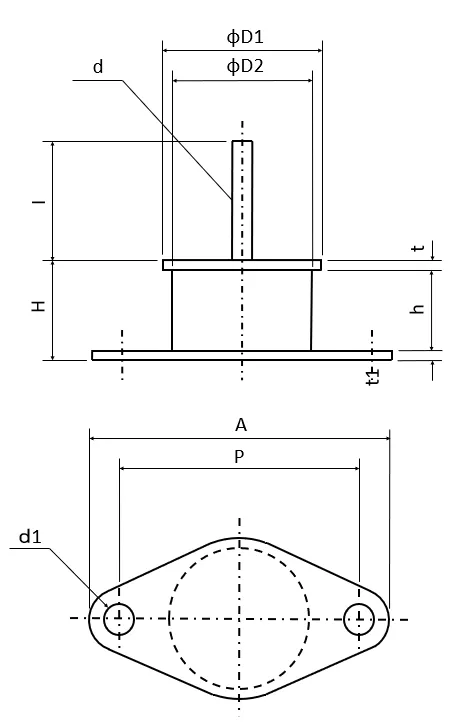

Dimensional Drawing

NV Series – Type A "Double-Sided Bolt-Fixed Type"

NV Series – Type B "Single-Sided Washer Type"

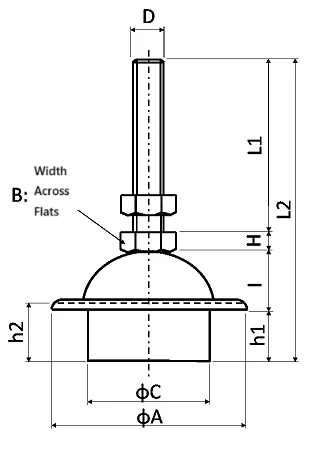

NVAd Series – Adjustable Type

Installation Instructions

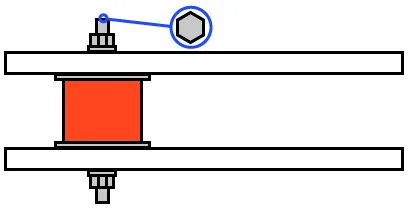

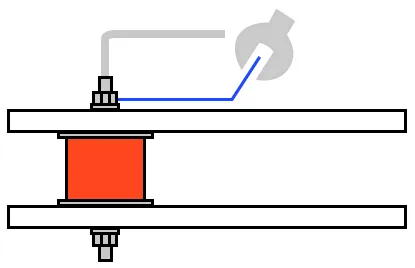

When installing, make sure the elastomer body is not twisted.

Twisting the body during installation may cause damage.

To prevent twisting, NonBuren products come equipped with a standard hexagonal hole.

During installation, insert a hex wrench into the hexagonal hole to keep the unit steady. This allows secure fastening without twisting.

-

Make sure the NonBuren does not twist during installation, and secure it firmly to the mounting surface.

Make sure the NonBuren does not twist during installation, and secure it firmly to the mounting surface.

Ensure that the mounting surface and the load-bearing surface are parallel to each other. -

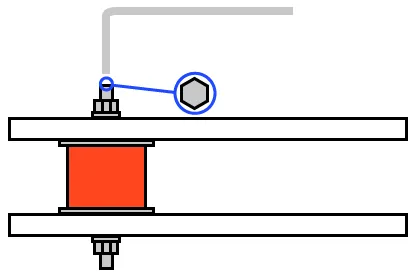

Insert a hex wrench into the hexagonal hole to prevent the NonBuren from rotating during installation.

Insert a hex wrench into the hexagonal hole to prevent the NonBuren from rotating during installation.

(Rotation may cause damage to the body.) -

Tighten the nut carefully while making sure the NonBuren does not twist.

Tighten the nut carefully while making sure the NonBuren does not twist.

This allows the NonBuren to be securely fixed without any twisting.

Proper Installation

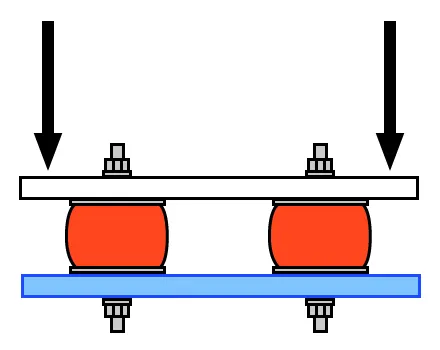

Ensure that the load is applied evenly during installation.

-

Under an Even Load

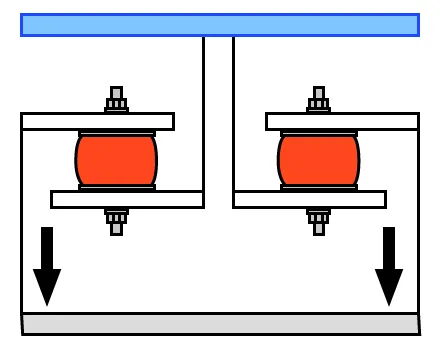

Under an Even Load Suspension in the Compression Direction Using a Stay or Similar Support

Suspension in the Compression Direction Using a Stay or Similar Support

Selection Procedure

-

Selection ProcedureExample of Actual Selection

-

Determine the number of anti-vibration mounts to support the load, and calculate the weight per mount.Compressor weighing 120 kgf supported at 4 points

→30kgf per mount -

Refer to the graph to find the appropriate NV Series part number based on the load that each anti-vibration pad can support.NV1S-40A(B) NV1S-58A(B) NV1S-90A(B)

-

If possible, ensure that the target vibration frequency is higher than the recommended frequency.

※You can estimate the frequency of the equipment based on the motor's rotation speed (rpm).

Example:○○○○(rpm)/(60 sec) = ○○(Hz)Compressor motor's rotation speed 1200rpm

→1200/60 = 20(Hz) -

If multiple part numbers are available, select the appropriate one by considering factors such as safety margin for load, vibration frequency, installation space, and cost.Based on load, frequency, and installation height, select NV1S-40.