Shock Absorption and Cushioning

NonBuren is a completely new type of shock-absorbing material that offers better impact cushioning than any conventional material.

NonBuren is known for its outstanding shock absorption. It is even said that an egg will not break when thrown onto it.

Its softness allows it to conform to the shape of the object, which helps spread the impact across a wider area and reduce surface pressure.This effect comes not only from its softness, but also from the way it spread the force.

It is a completely new type of shock-absorbing material that offers better impact absorption and cushioning performance than any conventional material.

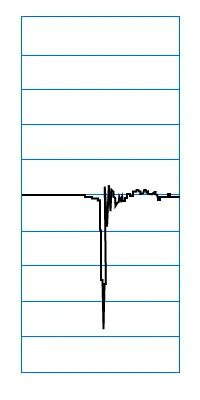

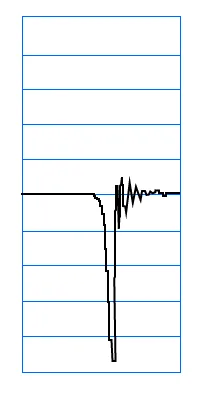

The comparison test uses a graph showing the impact force measured by sensors when a steel ball is dropped from a fixed height onto different materials.

NonBuren has been shown to absorb over 90% of impact energy, from light shocks to heavy impacts exceeding one ton.

※These are typical values and not guaranteed.

NonBuren has been used as a vibration-isolating pallet for safely transporting precision measuring instruments and precision machinery to factories overseas and in other locations.

Shock Cushioning

- Shock absorption for precision instruments during transport by attaching cushioning material inside shipping cases

- Protection against shocks caused by vehicle vibrations or sudden jolts, such as driving over curbs

- Shock protection for manhole covers used in underground fiber optic pits

- Shock cushioning during the transport of delicate items such as musical instruments or fragile goods

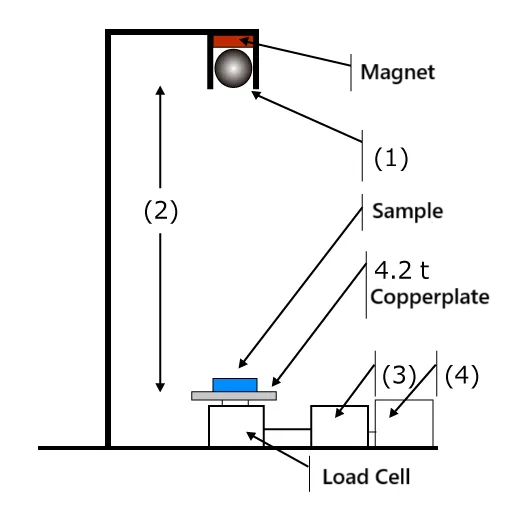

Shock Absorption Rate Comparison Test

| Test Method | Shock test using a falling steel ball. A steel ball is dropped onto the test sample, and the transmitted shock through the material is measured as impact force using a load cell. |

|---|---|

| Equipment | (1)Steel ball (535gr) (2)Drop height (690㎜) (3)Dynamic strain gauge (6002F Shinko Tsushin Kogyo) (4)Waveform recorder (8803 Hioki Electric) 1ton load cell |

| Evaluation | The test evaluates the peak shock load value when a steel ball is dropped directly onto a 4.2-ton steel plate, as well as the presence of residual vibration and whether the shock penetrates through the material. |

| Sample | NonBuren Sheet (Hardness: 0, 15, 30, 50, 70) Silicone gel, Silicone sponge (Other manufacturers) |

| Size | 100f㎜x10t㎜ |

| Impact Conditions | Collision speed 3.68m/s, Impact momentum 1.88kgm/s |

-

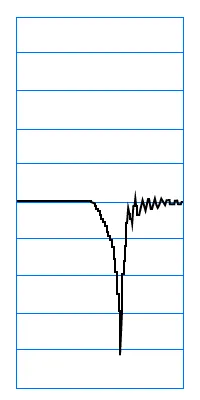

Shock penetration occurred

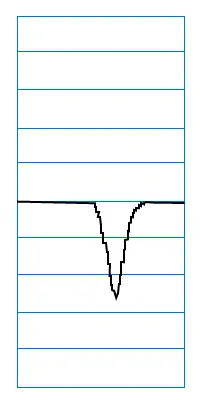

Impact value 200kg NonBuren Sheet S01scale=50kgm/s

NonBuren Sheet S01scale=50kgm/s -

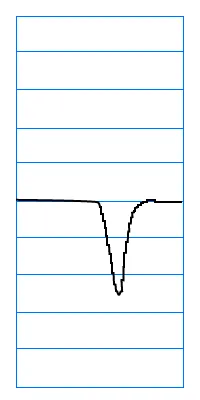

Impact value 120kg

NonBuren Sheet S01scale=50kgm/s

NonBuren Sheet S01scale=50kgm/s -

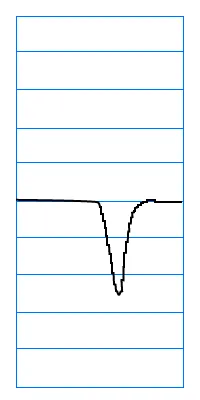

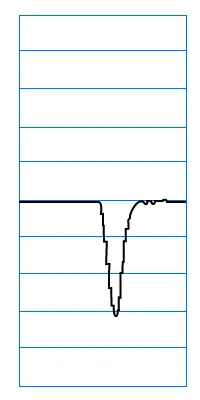

Impact value 120kg

NonBuren Sheet S151scale=50kgm/s

NonBuren Sheet S151scale=50kgm/s -

Impact value 125kg

NonBuren Sheet S301scale=50kgm/s

NonBuren Sheet S301scale=50kgm/s -

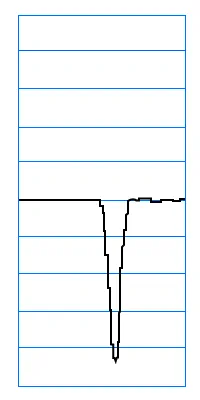

Impact value 150kg

NonBuren Sheet S501scale=50kgm/s

NonBuren Sheet S501scale=50kgm/s -

Impact value 220kg

NonBuren Sheet S701scale=50kgm/s

NonBuren Sheet S701scale=50kgm/s

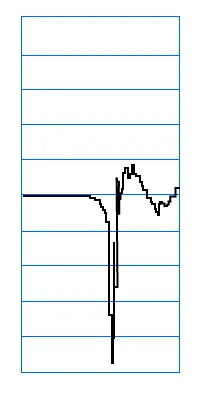

Silicone gel1scale=50kgm/s

Silicone gel1scale=50kgm/s

Silicone gel1scale=200kgm/s

Silicone gel1scale=200kgm/s

Silicone sponge1scale=50kgm/s

Silicone sponge1scale=50kgm/s

Silicone sponge1scale=200kgm/s

Silicone sponge1scale=200kgm/s