Protection from Vibration

Vibration is an unavoidable part of machine operation.

Increasing weight and rigidity can reduce vibration, but in reality, space and cost limitations often make it difficult to implement such measures

That's why we recommend NonBuren for effective vibration control.

It is especially suitable for use with motors, actuators, and other vibration-generating components.

NonBuren offers stable performance with minimal frequency dependence and no temperature drift, allowing it to handle a wide range of vibration types.

Its high vibration damping performance also makes equipment downsizing possible.

With a heat resistance of up to 70℃, along with excellent chemical and oil resistance, it can be used in a wide variety of environments.

It does not release outgassing substances such as low-molecular-weight siloxanes, making it safe for use in cleanrooms and food processing facilities.

Vibration Control

-

- Vibration control for large compressors and pumps

- Vibration isolation for desktop miniature compressors

- Vibration isolation for microscopes and measuring instruments that are sensitive to micro-vibrations, such as video microscopes

- Simply placing a high-performance gel sheet under the equipment provides an easy and effective vibration control solution

Protection for Precision Components

- Protection for Printed Circuit Boards and Hard Drives in Precision Equipment During Transport

- Vibration Control for Vehicle-Mounted Measuring Equipment (Automotive Anti-Vibration Material)

- Protection for controllers such as sequencers used in manufacturing equipment like presses and injection machines, where strong impacts occur

- Protection against lead breakage of electronic components on PCBs and damage to hard drives

- Vibration protection for hard disk drives

Customer Case Study:Vibration Control for a Large Compressor

A customer who had installed several large compressors contacted us for a solution to reduce the vibration transmitted to the floor.

After discussing the compressor's weight, dimensions, and possible vibration control methods with the customer, we visited them to check the actual conditions.

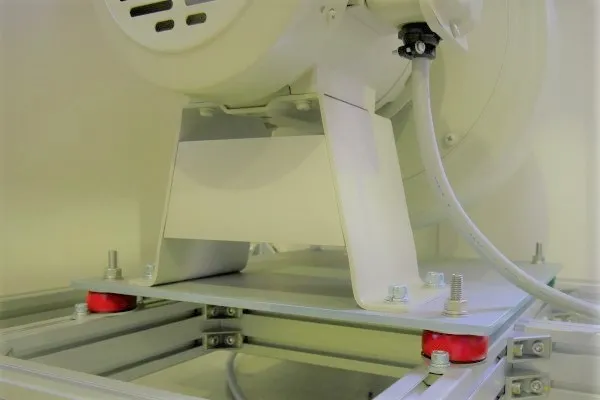

Based on the consultation, we decided to start by testing one unit. The original adjuster bolts were removed and「Round-Type Anti-Vibration Material "NonBuren Adjust" 」was installed for evaluation.

Investigation

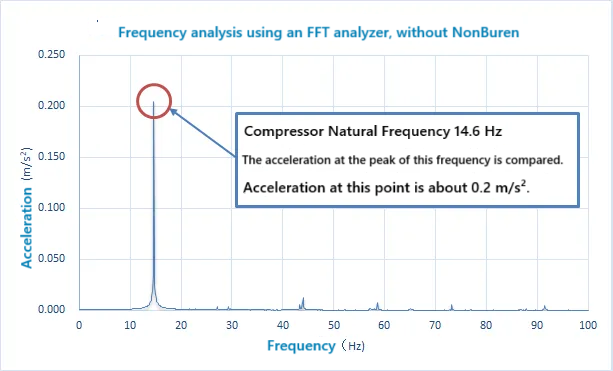

We began by using a vibration meter to measure how much the floor was shaking when the compressor was running. For the test, we selected the compressor that had the greatest impact on the floor among the multiple units and conducted a comparison with and without the anti-vibration material.

The compressor inside the unit was already using a black rubber vibration isolator, but it was assumed that it could not effectively isolate low frequencies such as 14.6 Hz. Since the compressor was installed on the top floor of the building, running multiple units at the same time caused vibrations not only in the adjacent room but also in areas below, such as storage rooms and meeting rooms, where desks and shelves were visibly shaking.

Installation of Round-Type Anti-Vibration Materials

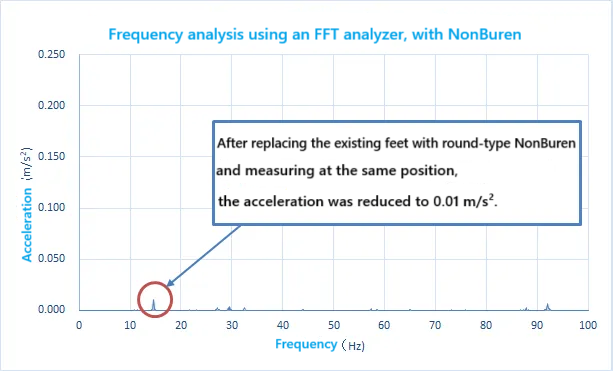

After the inspection, we removed the existing adjuster and replaced it with the round-type "NonBuren Adjust". Measurements were then taken at the same location.

Results

The vibration around 14 Hz was reduced to about one-tenth to one-twentieth of the original level. The decrease was noticeable even by feel, and the customer was pleased with the results.